3D-Printing Microfluidics for Space

ProtoFluidics

3D-printing microfluidics for bio-testing in outerspace.

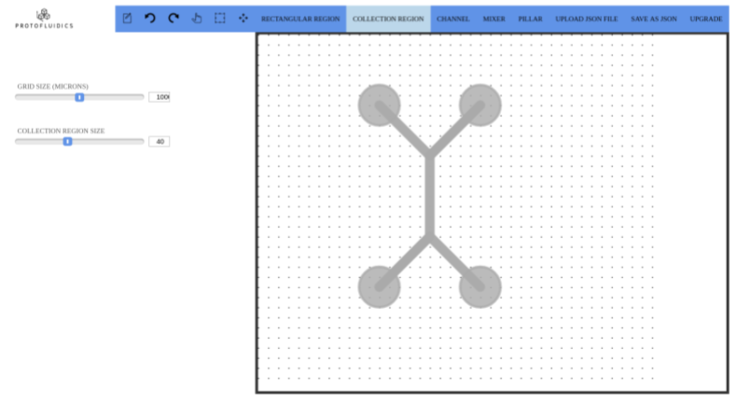

ProtoFluidics was created to address the gap between researchers who can 3D-print devices for 1/5 of the cost as standard methods but lack the 3D-modeling knowledge to do so. We programmed in a library of the most popular types of microfluidic parts for designing 3D-printed microfluidics. The graphical interface was built with HTML, CSS, and JavaScript and integrated with OpenSCAD for visualizing 3D designs.

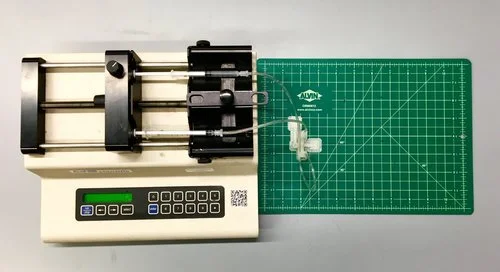

Our tests showed that 3D-printed microfluidics had 90% efficacy as traditionally-made ones. However, the benefits of 3D-printing them were cost-effectiveness and convenience for use in outer space, where supply load space was scarce and researchers had to adapt their biomedical tools for different experiments.

Our team consisted of Adam Zachar, Jamie Carlson, and me. We won 1st Place at the 2017 National Space Society Manufacturing Competition, granting us a microfluidic print with our software on the International Space Station!

Let’s work together.

If you have a project in mind, or would like to chat, shoot me an email at laura.y.gao@gmail.com.